iPhone Charger PCB Manufacturing Company in Vietnam

iPhone Charger PCB Manufacturing Company in Vietnam

In the field of manufacturing phone charger components, PCB circuit is the “heart” that determines the performance and durability of the product. Especially, withiPhone charger, the requirements for electrical safety and battery balancing ability are set at the highest level. In Vietnam, Company MyMy Technology is currently one of the iPhone charger PCB manufacturing unit reputation, stable supply assurance and circuit design meets international standards.

1. iPhone charger PCB circuit – the deciding factor for durability and safety - MyMy Technology

In every iPhone charger,mạch PCB (Printed Circuit Board)plays a role in connecting electronic components such as capacitors, inductors, diodes and control ICs. The main task of PCB is toStabilizes current, balances voltage and protect iPhone battery from overload or short circuit.

A high quality PCB helps stable charging current, does not cause the charger to heat up, does not affect battery life and especially avoids the phenomenon"virtual charging"– the device does not receive enough power even though it shows it is charging.

In MyMy, the entire PCB manufacturing process is strictly controlled: from selecting flame-retardant FR-4 boards, processing 1oz standard copper layers to coating glue to protect components from moisture and electric shock. Each circuit is tested under load conditions of 5V–3A, 9V–2.2A and 12V–1.67A – perfectly compatible with iPhone models from 8 to 15 Pro Max.

2. iPhone charging circuit structure and operating principle

A standard iPhone charging circuit consists of the following main components:

- Power control IC:Helps to identify input voltage and adjust charging power accordingly.

- Diode bridge and inductor:Convert AC to stable DC.

- Noise filter capacitor:Eliminates surges, making charging smooth and safe.

- Thermal sensor:Monitor temperature during charging, cut off circuit when overheating is detected.

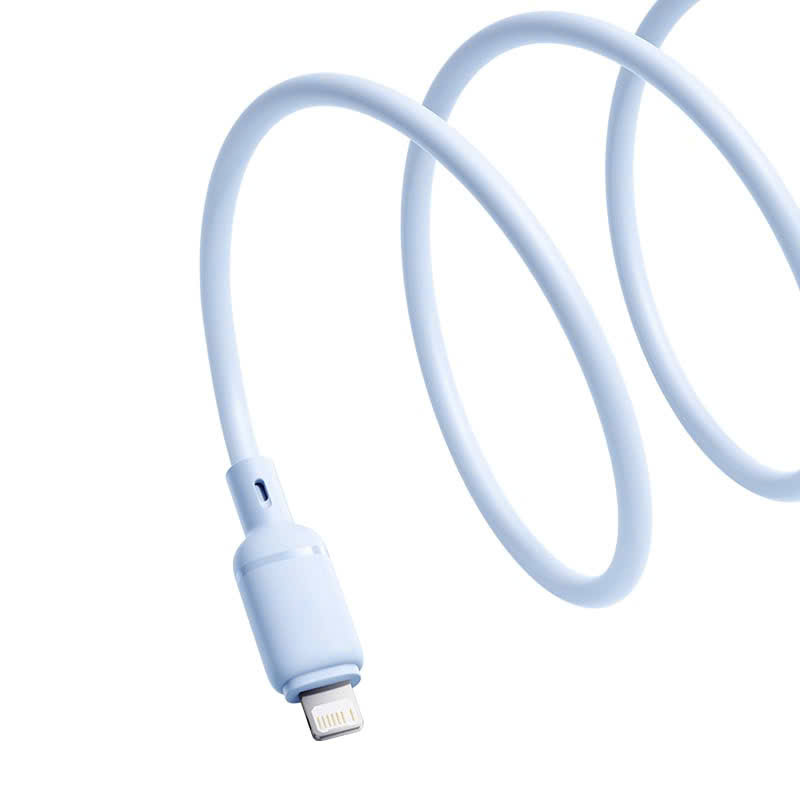

- Type-C or Lightning port:Connects to a cable, transmitting current to the device battery.

The circuit is designed3 parallel copper conductive layersaimed ateven heat distribution and reduce power loss, helping the charger maintain high performance while remaining cool during long-term operation.

3. Stable supply of charging circuits – a strategic factor for electronics assemblers - MyMy Technology

One of the strengths that makes MyMy a leading partner ofiPhone charger assembly factory in Vietnam To be stable PCB supply capacity.

With more capacity500,000 circuits/monthMyMy maintains a source of genuine imported components from Korea and Japan, and hasSMT automatic lineAllows surface mount of components with accuracy below 0.05mm.

Thanks to that, each charging circuit produced has high uniformity, limiting welding errors, resistance error below 1%. This helps partner businesses save on inspection costs, shorten assembly time andMaintain stable progress of iPhone charger shipment to the market.

4. 3S 3V battery balancing charging circuit - used in high-end chargers - MyMy Technology

Not only stopping at standard chargers, MyMy Technology also develops 3S 3V battery balance charger circuit– a step forward in lithium battery protection technology.

This circuit is designed for chargers or power storage devices using3 battery cells connected in series (3S), each cell has a nominal voltage of 3V – 3.7V. The automatic balancing circuit system adjusts the voltage between cells,Avoid voltage deviation and prevent battery swelling.

Operating principle: When a cell reaches a voltage higher than the allowed level, the circuit will activate the transistor to discharge some current, bringing the cells back to a state of balance. This mechanism helps increase battery life by 30–40%, while maintaining stable power for the charger during fast charging.

5. Outstanding advantages of PCB circuits produced by MyMy Technology

- Fireproof – anti-electric leakage:High quality FR-4 material, heat resistant up to 130°C.

- High precision:Voltage error less than 0.5%, ensuring perfect compatibility with iPhone.

- Optimized heat dissipation:Multi-layer design helps to transfer heat quickly, keeping components safe.

- PD – QC fast charging compatibility:Integrated circuit recognizes Power Delivery and Quick Charge protocols.

- Multi-layered protection:Includes overcurrent, overvoltage, short circuit, overtemperature and reverse polarity protection.

Thanks to these advantages,MyMy PCBChosen by many Vietnamese OEM brandshigh quality iPhone charger manufacturing, both meeting technical standards and ensuring competitive prices.

6. MyMy – a reputable charging circuit manufacturing partner in Vietnam

With more than 10 years of development in the field of electronic components, MyMy Company has built a specialized PCB manufacturing factory in the industrial park in the North of Vietnam, meeting ISO 9001:2015 and RoHS standards.

The AOI (Automatic Optical Inspection) system is used to detect micro-circuit soldering errors at the micrometer level, ensuring that the products leaving the factory are of absolute quality.

MyMy currently not only supplies circuits for iPhone chargers but also expands to product lines:backup battery circuit, wireless charging circuit, 3S 3V battery balance circuit and lithium-ion cell protection circuit.

Thanks to that, businesses are alwaysSustainable PCB supply for Vietnam's electronics industry, contributing to reducing dependence on imported components.

7. Conclusion - MyMy Technology

The PCB is the foundation of every iPhone charger – a convergence of sophisticated electronics and precision manufacturing technology.

In Vietnam,MyMy Companyasserting its positiontop iphone charger pcb manufacturer, providing high performance, safe and user-friendly products.

With sustainable development, MyMy commits toProvides a stable charging circuit, balancing 3S 3V batteries according to technical standards, meeting all production needs of smart chargers and new generation electronic devices.