Address of iPhone Charger PCB Circuit Manufacturing in Vietnam

Address of iPhone Charger PCB Circuit Manufacturing in Vietnam

1. Introducing the role of the PCB circuit in the iPhone charger

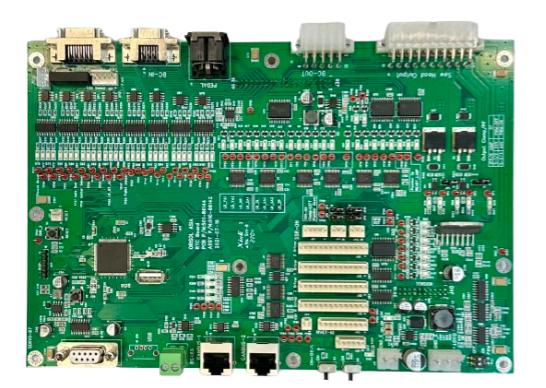

In eachiPhone charger, mạch PCB (Printed Circuit Board)play a central role in helping control, stabilize and protect charging current. A quality PCB circuit not only helps the phone charge faster but alsoExtends battery life and reduces heat generated during charging.

In Vietnam, many businesses have invested in modern SMT lines, notablyInternational standard iPhone charger PCB manufacturing factories, like MyMy Technology– component supplier for many major fast charger and mobile accessory brands.

To understand the circuit design and testing process, let's learn high - voltage - current - power calculation and factors that directly affectiPhone charging performance.

2. Formula for calculating voltage - current - charging capacity

The working principle of the charging circuit is based on the relationship between voltage (V), electric current (I) and power (P)according to the basic formula:

P = V × I

For example:

An iPhone charger with output5V – 2Awill give maximum power of:

P = 5 × 2 = 10W

If it is a fast charger9V – 2.2A, capacity achieved:

P = 9 × 2.2 = 19.8W

This is why fast charging models canReduce charging time by 50–70%compared with conventional chargers.

In PCB design, engineers must calculate to ensure stable output voltage, avoid fluctuations exceeding ±5% compared to Apple standard (Lightning 5V ±0.25V).

3. How to determine the appropriate resistor for TP4056 charger IC

IC TP4056is a popular charging chip line in Lithium-Ion battery charging circuits. ResistorRprogmounted at the “PROG” pin of the IC to determine maximum charging current (Icharge)according to the formula:

Icharge = 1200 / Rprog (kΩ)

For example:

- Rprog = 1.2kΩ → Icharge = 1000mA

- Rprog = 2.4kΩ → Icharge = 500mA

From here, the manufacturer can adjust the resistance value to suit the battery capacity and charging standard of the device.

4. Example of calculating resistance value and charging current

Suppose you need to charge an iPhone battery with a capacity of 3000mAh with time about2 hours.

We need charging current of about:

I = Capacity / Time = 3000 / 2 =1500mA (1.5A)

From the TP4056 IC formula:

Rprog = 1200 / 1500 =0.8 kΩ

Engineers can choose 0.82kΩ resistor to achieve actual charging current of ~1.46A.

This value ensures justFast charging while protecting the battery, and does not overheat.

5. How to calculate phone battery charging time accurately

General formula for estimating charging time:

T (hours) = (Battery capacity × 1.2) / Charging current

Factor 1.2 is used to compensate for power loss (about 20%).

Example: 3000mAh battery charging at 1.5A →

T = (3000 × 1.2) / 1500 = 2.4 hours

If the charger uses a high efficiency PCB (over 90%), the time can be reduced to 2 hours.

6. Factors affecting charging speed

Charging speed depends not only on current but also on:

- Energy conversion efficiency of the PCB circuit.

- Ambient temperature and heat dissipation capacity of the charging case.

- Quality of charging cable and Lightning/USB-C connection port.

- Lithium battery life and remaining capacity.

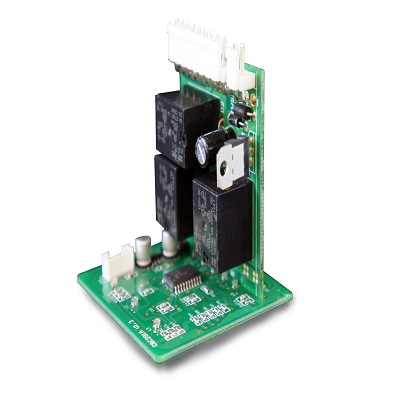

Therefore, in production, PCB circuits need to beOptimize layout design, especially the areaMOSFET and rectifier diode to ensure stable current transmission, reduce power loss.

7. Relationship between current and circuit temperature

As the current increases, circuit losses also increase with the square of the current.(P = I²R). This makes component temperature increase rapidly if the resistance is not optimized.

Therefore, PCB engineers need to choose thick copper material (35µm – 70µm), use a wide pathfor high load areas, andPlace filter capacitor near power ICto avoid local heat generation.

Modern factories in Vietnam such as MyMy Technology appliedHigh heat resistant FR4 material, helps the circuit operate stably in 0–85°C environment, meeting European export standards.

8. Analysis of the energy conversion efficiency of the circuit

Charging circuit efficiency typically ranges from80–95%, depending on the circuit structure (buck, boost, buck-boost).

For example:

- Buck circuit: efficiency ~90–95%.

- Boost circuit: efficiency ~85–90%.

High performance PCB circuit helps reduce power consumption, limit heat dissipation, and increase the durability of components– key factor in achieving standards Apple MFi (Made for iPhone).

9. Optimize power to save and reduce heat

Engineers at theVietnam PCB factory commonly applied solutions:

- Use Charging IC has sleep mode when the battery is full.

- Reduce loss on MOSFETby choosing the type with low Rds(on).

- Additional High quality filter capacitors and inductors to reduce oscillation.

- Design heat sink with thick copper layer, helps stabilize the current for a long time.

Thanks to this, the charger operates cooler, increasing safety when charging overnight or in a closed environment.

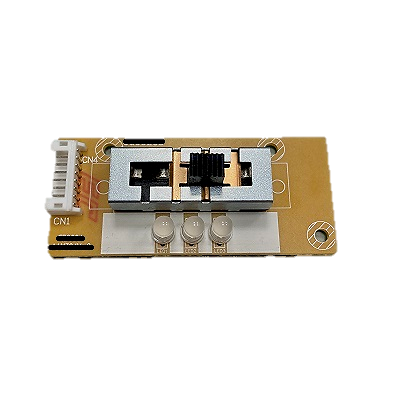

10. How to check stability and verify output power

After completing the circuit, the engineer conducts a test using power and voltage fluctuation measuring devices.

An Apple standard PCB needs:

- Output voltage error≤ ±5%.

- Current fluctuation≤ 2%when load changes.

- Component temperature< 80°C when running continuously for 2 hours.

At factories like MyMy Technology, the inspection process is automated by the system AOI – ICT – Burn-in Test, helps ensure circuit meets power standards 5V–3A, 9V–2.2A, 20V–1AFast charging compatible with iPhone, iPad and new Apple devices.

Conclude

From the current – voltage – power calculation arrive output performance testing, PCB circuit plays a decisive role in the quality of iPhone charger. Selectionreputable PCB manufacturing address in Vietnamnot only ensures user safety but also contributes to enhance the value of Vietnamese components in the international market.

Company MyMy Technology is one of the pioneers in manufacturing Apple standard charging circuits, providingComprehensive PCB design – manufacturing – testing solutions for domestic and foreign enterprises.

Address of iPhone Charger PCB Circuit Manufacturing in Vietnam