iPhone Charger PCB Circuit Board Manufacturing Factory in Vietnam

-

iPhone Charger PCB Circuit Board Manufacturing Factory in Vietnam

-

-

1. Understanding the role of the PCB circuit in the iPhone charger

- In every iPhone charger,mạch PCB (Printed Circuit Board)is the core component – the place that controls all electrical activities, balances energy and protects the safety of the device. This is the “heart” that helpsStable and constant charging source, avoids short circuit and prolongs battery life.

- PCB has the taskalternating current (AC) power conversionfrom socket todirect current (DC)suitable for battery charging. In addition, the circuit board also integratesOvervoltage protection, current limiting, thermal management and battery balancing functions– especially in modern fast charging lines 20W, 30W.

- For iPhone models using Li-ion batteries, the PCB charging circuit helps the device self- regulating voltage according to charging stage, ensuring safe charging process, without causing battery damage or reducing performance.

-

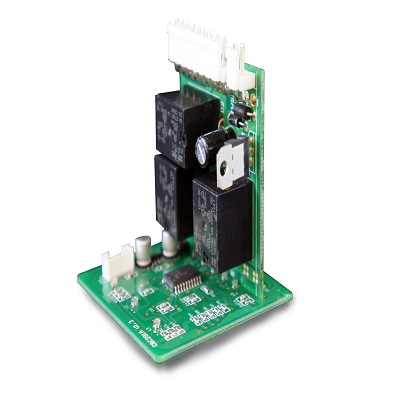

2. Basic structure of iPhone charging circuit MyMy Technology

- One Industrial standard iPhone charging circuit consists of 5 main parts:

- Rectifier and noise filter:Converts AC current to smooth and stable DC current.

- Regulator circuit:Maintain voltage at appropriate level (5V–20V depending on charging capacity).

- Power MOSFET and charging IC:Control current rate, prevent overcharging or reverse discharge.

- Overvoltage – overcurrent protection circuit:Circuit breaker in case of fault to protect components and battery.

- Temperature sensor and battery balance circuit:Monitor temperature and distribute charging current evenly between battery cells (e.g. 3S 3V battery circuit).

- Thanks to this structure, the PCB circuit in the iPhone charger ensures high charging efficiency, just limited fire and explosion risk, and meets international safety standards CE - RoHS.

-

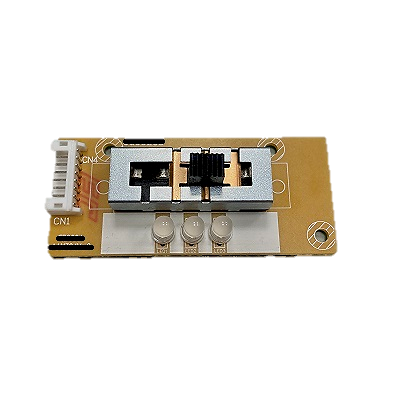

3. Battery balancing charging circuit and its role in the 3S 3V system

- In multi-cell battery packs, such as 3S batteries (3 cells in series, each cell 3.7V), the PCB charging circuit plays a role in balancing the voltage between the cells. Without this circuit, a single cell being overcharged or discharged would damage the entire battery pack.

- The smart battery balancing circuit in today's chargers can automatically power cut-off when the optimum voltage level is reached, at the same time-discharge high cell energy to balance. This is especially important withiPhones and mobile devices with large capacity batteries, helps optimize charging cycles and increase battery life by up to 20–30%.

- 4. Operating principle of the charger PCB circuit

- The PCB circuit in the iPhone charger works according toCC–CV (Constant Current – Constant Voltage) cycle:

- Stage 1 – Constant Current (CC):When the battery is low, the charger provides a steady current for quick recharging.

- Stage 2 – Constant Voltage (CV):As the battery approaches its maximum level, the PCB circuit gradually reduces the charging current to protect the battery.

- Phase 3 – Smart charging cut-off:When the battery reaches 100%, the circuit automatically cuts off the current to avoid overcharging.

- Thanks to this mechanism, the charging current is always stable and constant – guaranteedThe safest and most efficient power supply for the iPhone.

-

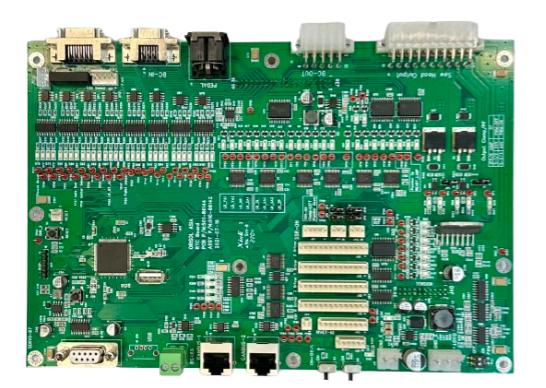

5. Manufacturing standards for iPhone charger PCBs in Vietnam

- ThePCB factory in VietnamCurrently applying advanced technology lines that meet international standards. The production process usually includes:

- PCB material selection:

- Use FR4, aluminum, or high thermal conductivity ceramics to ensure good insulation and efficient heat dissipation.

- Use FR4, aluminum, or high thermal conductivity ceramics to ensure good insulation and efficient heat dissipation.

- Copper circuit prototyping & etching:

- Using technology CNC and multi-layer thermoforming, ensuring micrometer precision in the signal path.

- Using technology CNC and multi-layer thermoforming, ensuring micrometer precision in the signal path.

- Component Mounting (SMT/AI):

- The automatic pick and place machine installs IC components, capacitors, inductors, and MOSFETs in the correct position.

- The automatic pick and place machine installs IC components, capacitors, inductors, and MOSFETs in the correct position.

- Welding & Quality Control:

- Using techniques wave soldering or reflow soldering, then check AOI (Automatic Optical Inspection)to eliminate micro errors.

- Using techniques wave soldering or reflow soldering, then check AOI (Automatic Optical Inspection)to eliminate micro errors.

- Testing & Load Testing:

- Each circuit is tested with actual voltage (5V–20V) to ensure stable charging current, no overheating and maximum performance.

- Each circuit is tested with actual voltage (5V–20V) to ensure stable charging current, no overheating and maximum performance.

-

6. Advantages of manufacturing iPhone charger PCB in Vietnam MyMy Technology

- Vietnam is becomingSoutheast Asia's leading mobile phone charger component manufacturing center, thanks to the factors:

- Modern automated production line:Reduce errors and increase productivity.

- Optimal production cost:Strong competition with China and Korea.

- Team of highly qualified electronic engineers:Ability to design, test and customize circuits according to brand requirements.

- Complies with international safety standards:Make sure the iPhone charger works stably and is compatible with all device lines.

- Thanks to that, theiPhone charger PCB manufacturing factory in Vietnamcan meet OEM - ODM needs for large enterprises, fromCustom design, brand logo printing to complete assembly.

- 7. Application of iPhone charger PCB MyMy Technology

- In addition to the iPhone charger,charging PCB circuit, also used in many other products:

- iPad charger, MacBook, wireless headphones, backup battery.

- Charging circuit3S 3Vused in IoT devices, LED lights, cameras.

- Charging circuitLi-ion battery balancing for mini electric cars and home appliances.

- All requiredStable power supply, intelligent protection circuit and optimal heat management– something that a high quality PCB can provide.

-

8. Reputable iPhone charger PCB manufacturing partner MyMy Technology

- In Vietnam, factories such as MyMy Technology, High Leap Electronic, and VietPCBare prestigious units in the manufacturing field.iPhone – iPad charging PCB circuit.

- These businesses provide services design, manufacture, assemble and test in one package, meet all requirements for:

- Charging capacity (5W – 30W)

- Current, temperature, and pressure protection features

- Optimize component performance and durability

- Support bulk orders, nationwide delivery

-

Conclude

- iPhone charger PCB circuitnot only is it the foundation for a stable charging current, but it is also the key factor that helpsBattery operates durably, safely and efficiently With increasingly modern production and inspection capacity,Vietnam is emerging as a reputable regional source of charging circuits., meeting the strict requirements of leading electronics brands.

- If your business needsOrder high quality iPhone charger PCB circuit, 3S 3V battery balance, design on request, please contact us immediately factory MyMy Technology hoặc High Leap Electronicfor detailed advice and receivefastest quote.

- iPhone Charger PCB Circuit Board Manufacturing Factory in Vietnam