Power Bank PCB Circuit Board Manufacturing Factory In Vietnam

Power Bank PCB Circuit Board Manufacturing Factory In Vietnam

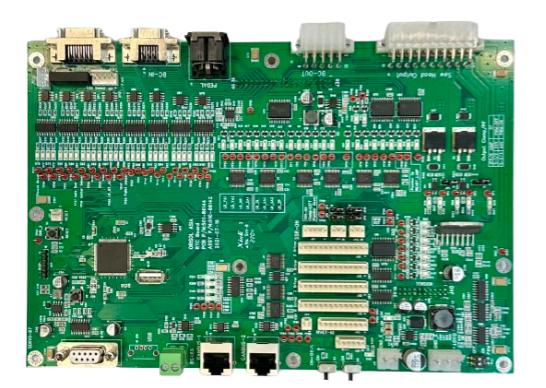

Power banks have become an indispensable item, but behind the convenient fast charging ability is a complex printed circuit board (PCB) that acts as an energy and safety management system. The quality of the PCB circuit in the power bank not only affects the charging speed but also directly determines the battery life and risk of explosion.

Choosing a Power Bank PCB Circuit Board Manufacturing Factory In VietnamReputation, ability to master thermal management technology and multi-layer protection, is the key factor for the success and safety of the product.

Technical Factors That Determine the Durability of a Charging Circuit

The durability and stability of a power bank circuit is determined by a combination of factors that go far beyond simply using expensive components.

Continuous Charging Heat Reduction Circuit Design

Heat is the biggest enemy of electronic components and batteries.Continuous Charging Heat Reduction Circuit Designrequire:

- Wide copper vein:High current transmission lines need to be designed wider and thicker to reduce resistance, thereby Thermogenesis and Reduce Electronic Component Wear and Teardue to thermal stress.

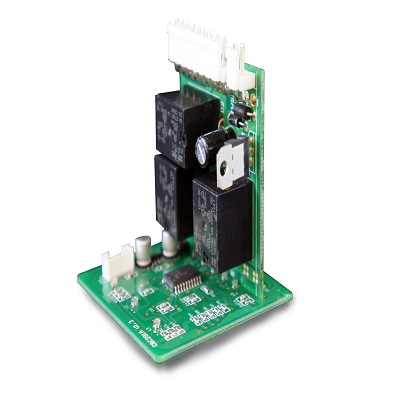

- Integrated Heat Dissipation System On PCB:Use the holesThermal Viato conduct heat from heat-generating components (IC, Mosfet) to the copper layers inside the PCB, enhancing the abilityMulti-level Protection System

A reputable PCB should incorporate at least three basic protection mechanisms:

- OVP (Over Voltage Protection):Protects the circuit from excessive input voltage.

- OCP (Over Current Protection):Disconnects when charging/discharging exceeds safe threshold.

- OTP (Over Temperature Protection):Shut down all operations when circuit temperature is too high.

. Stable Power Management Chip (PMIC/IC Controller)

The management chip must be able to holdExtremely stable output voltage and current(low ripple). Stable charging current willIncreased Battery Life Thanks to Stable PCB Circuit because it minimizes chemical stress on Lithium-ion battery cells.

Conformal Coating

In the hot and humid climate in Vietnam, Conformal Coating is a necessary factor toProtect the Battery and Internal Components of the Chargerfrom moisture corrosion. This coating helpsPCB Stable Operation for Many Years by isolating the circuit from the environment.

Technical Solutions to Enhance Safety and Battery Life

Modern power bank PCB circuit is not just about power transmission but also the brain that controls safety and optimizes charging performance.

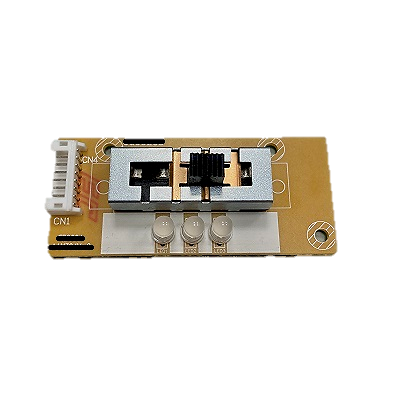

Adaptive Charging Current Management

A smart charger circuit must know how to "communicate" with the device being charged:

- How to Adjust Charging Current for Each Device:The PCB integrates a protocol controller chip (like USB-PD Controller) to negotiate optimal voltage and current levels with the mobile device (iPhone, Android). This precise adjustment ensures fast yet safe charging, avoiding overcharging the device.

- Reduce Electronic Component Wear:By maintaining the charging current at its highest and most stable performance level, the PCB minimizes the need for components to operate under harsh fluctuating conditions, extending their operating life.

High Quality PCB Reduces Risk of Short Circuit

The risk of short circuits usually originates from manufacturing defects (uncontrolled open/short circuits) or lack of protection circuits.

- Precise manufacturing process:Reputable factories use automated optical inspection (AOI) technology to eliminate potential manufacturing defects.

- Built-in Protection Circuit (BMS): High Quality PCB Reduces Risk of Short CircuitThanks to the full BMS system integration, with high quality semiconductor components (FET), capable of respondingOptimized Battery Life – Protection Circuit Doubles Durability

The protection circuit not only prevents instantaneous failures but also prolongs the overall life of the battery.

- Charge/Discharge Cycle Protection:The battery management circuit (BMS) on the PCB accurately controls the Charging Cut-off Voltage and Discharging Cut-off Voltage. Preventing the battery from overcharging and over-discharging is key toProtection Circuit Helps Backup Battery Last 2 Times Longer compared to batteries without standard protection circuit.

- Stable in Continuous Charge/Discharge: How to Make PCB Work Stable for Many Years?The answer lies in the use of highly reliable components, especially long-life, heat-resistant capacitors, which help the circuit maintain stable voltage conversion performance for thousands of hours of use.

Conclude

MyMy Technology is a pioneer in this field. MyMy Technology not only provide complex multi-layer PCB solutions for high-power power banks, but also focus on applying thermal optimization techniques and integrating advanced BMS systems. By prioritizing theSolutions to Reduce Electronic Components Wear and Tear and High Quality PCB Reduces Risk of Short Circuit, MyMy Technology Ensure that each charging circuit product meets the most stringent durability and safety standards, bringing absolute trust to consumers and competitiveness to businesses.

Power Bank PCB Circuit Board Manufacturing Factory In Vietnam