Power Bank PCB Manufacturing Company in Vietnam

Power Bank PCB Manufacturing Company in Vietnam

Printed Circuit Board (PCB) is an indispensable component, the electronic foundation for all modern products. ForPower Bank– essential mobile devices, the quality of the PCB circuit determines the power management ability, charging speed and especially safety. OnePower Bank PCB Manufacturing Company in Vietnamreputation not only provides high quality circuits for Power Bank but also is a strategic partner in many other high-tech industries.

1. Platform Application: PCB In Power Bank And Mobile Devices

The PCB circuit in the power bank acts as an intelligent power management system, controlling complex functions:

- PCB Applications In iPhone Chargers And Mobile Devices:In power banks and chargers, the PCB is responsible for voltage conversion (Boost/Buck Converter), battery charge/discharge management (Battery Management System - BMS) and communication with mobile devices via fast charging standards (PD, Quick Charge). The quality of the PCB determines the energy conversion efficiency and battery life.

- PCB For Wireless Charging Line – Future Technology:For wireless power banks, PCBs integrate inductors and high-frequency oscillation circuits, which require materials with stable dielectric constants to optimize wireless power transmission performance.

2. Multi-Industry Applications of PCB Circuits

The capacity of a reputable PCB manufacturing company in Vietnam is demonstrated through its ability to produce circuits for many fields requiring high technology:

2.1. Technology and Automation

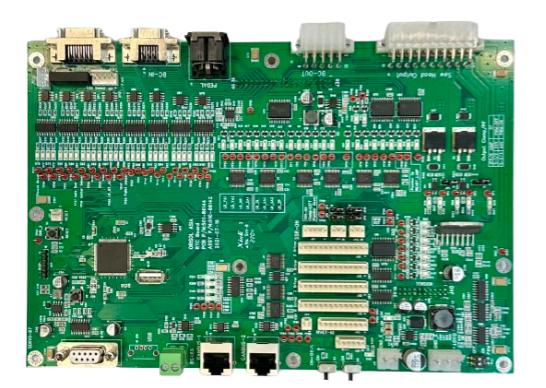

- The Role of PCB in Computer Components:Multi-layer PCB is the core of Motherboard, graphics card (GPU) and memory (RAM), where Signal Integrity requirements are extremely strict due to high data processing speed.

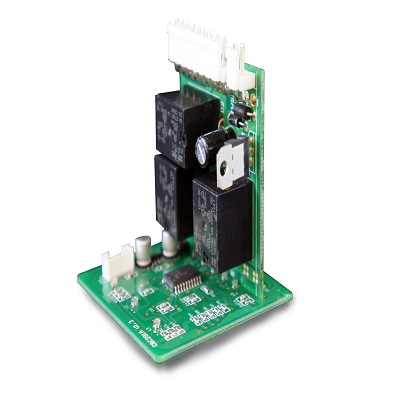

- PCB In Industrial Automation Systems:PCBs in industrial environments must be of the typeRigid-Flex PCB or Metal Core PCB, has good mechanical strength and heat resistance, anti-interference ability to control PLC controllers and robot arms.

2.2. Special and Smart Electronics

- PCB Circuits In Smart Home Appliances:From refrigerators and washing machines to smart lighting systems, PCBs manage wireless communication (Wi-Fi, Bluetooth) and control sensors. The main requirements are durability and optimal manufacturing costs.

- PCB In IoT Sensor System:IoT (Internet of Things) sensors require PCBs to be compact, low power consumption, and are often usedMicro PCB and Single/Double Layer PCBhigh density

3. Specialized Technical Areas

Applications requiring PCBs with high material specialization and anti-interference:

3.1. Transport and Telecommunications

- PCB in Automotive Industry – New Electrification Trend:The trend of electric vehicles (EVs) and autonomous driving drives the demand for high-temperature, high-reliability PCBs (IPC Class 3/3A). PCBs are used in BMS systems for EV batteries, motor controllers, and ADAS driver assistance systems.

- PCB For Telecommunications And Data Transmission Industry:High-Frequency PCBs require special materials such as Teflon (PTFE) to ensure the lowest signal loss for 5G base stations, routers and high-speed network switches.

3.2. Sound and Lighting

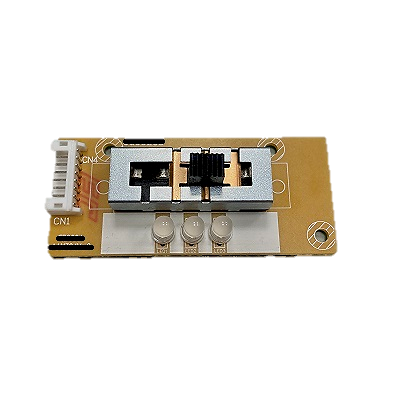

- Anti-interference PCB Application in Audio:PCBs in high-end audio devices (Hifi, Amplifiers) must be designed with strict signal trace and power trace separation techniques toOptimizing Circuits to Reduce Noise, ensuring pure sound quality.

- PCB In High Efficiency LED Manufacturing: Use Metal Core PCB (MCPCB), usually aluminum, to quickly dissipate heat from the LED chip. This is essential to prolong the life and maintain the luminous efficiency of the LED.

4. The Importance of PCB Manufacturing Companies in Vietnam

Choosing a local PCB manufacturing partner offers advantages in logistics, cost and the ability to meet a wide range of technical standards. A reputable company should have the flexibility to switch between PCB types: from simple two-layer PCBs for home appliances to complex multi-layer PCBs for high-end power banks and high-frequency PCBs for telecommunications.

Conclude

The power bank and mobile device market demands constant innovation and quality. A successful PCB manufacturing company in Vietnam must combine advanced manufacturing technology with a deep understanding of industry standards.

MyMy Technology lis a typical example ofPower Bank PCB Manufacturing Company in Vietnam has a diverse manufacturing capability. The unit not only provides optimal PCB solutions for power banks and iPhone chargers (including BMS and fast charging requirements), but also demonstrates the ability to produce high-quality circuits for more challenging applications such asPCB in Automotive Industry and PCB For Wireless Charging Line. Select MyMy Technology is to choose the assurance of quality, reliability and technological flexibility for every electronics project.