Power Bank PCB Manufacturing in Vietnam

Power Bank PCB Manufacturing in Vietnam

A power bank is more than just a battery; it is a complex electronic device in which,Mạch In PCB (Printed Circuit Board)acts as an intelligent energy management system, controlling the entire charging and discharging process. Power Bank PCB Manufacturing in Vietnam is evolving rapidly, focusing on meeting high technical standards for large capacity batteries, high power fast charging and smart features.

A reputable PCB manufacturing company needs to master complex printed circuit technologies to create safe, efficient and durable power bank products.

1. PCB For High Power Power Bank Series

The need for fast charging and large capacity poses major challenges in thermal management and current transfer on PCB circuits.

1.1. PCB In Large Capacity Power Bank - MyMy Technology

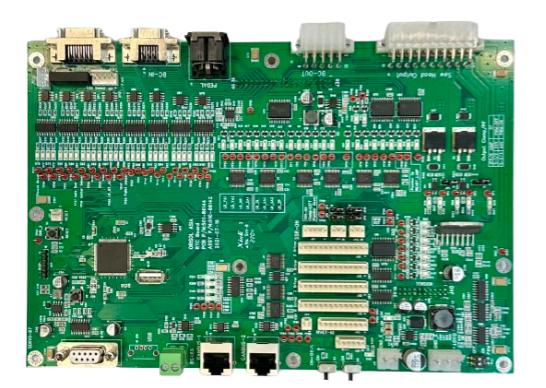

Large capacity power banks (over $20,000 \text{mAh}$) use multiple battery cells, requiring the PCB to integrate aLi-ion and Li-Polymer Battery Control Circuitmore complex (BMS - Battery Management System). The PCB must be able to simultaneously monitor multiple battery strings, manage heat and balance voltage between battery cells to ensure safety and extend the overall life of the battery pack.

1.2. Printed Circuit Board For 20W - 30W Fast Charging - MyMy Technology

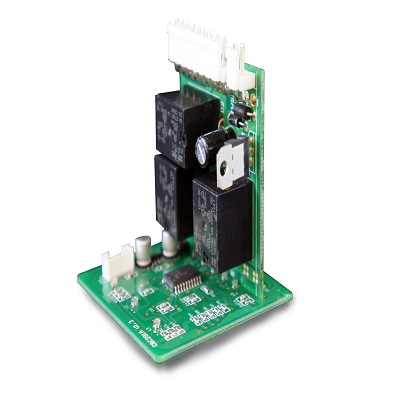

High power fast chargers 20W, 30W and above need PCBs capable of handling large currents without overheating.

- Multi-Layer PCB:Usually 4-layer or 6-layer PCB to distribute large power lines, minimize impedance and heat generation.

- GaN components:The printed circuit board must be optimally designed to integrate semiconductor components.Gallium Nitride (GaN), which helps to reduce circuit size and increase conversion efficiency.

1.3. PCB For Power Bank With Built-in Type-C Port - MyMy Technology

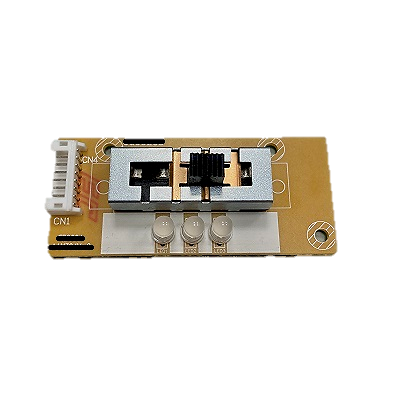

The move to the portal Type-C and standardUSB Power Delivery (USB-PD) requires the PCB to integrate a PD controller chip. The printed circuit board must ensure stable communication data transmission between the power bank and the device being charged to negotiate the correct voltage.

2. Integrated Circuit and Intelligent Solutions

The market is shifting to more complex power banks, which require intelligent PCB design.

2.1. Circuit Solution For Integrated Battery With Bidirectional Charging - MyMy Technology

Modern power banks are capable of charging a device and recharging itself via the same Type-C port (two-way charging).Circuit Solution For Integrated Battery Bidirectional Charging requires the PCB to have a complex control IC that can flexibly switch between modesBoost(increase voltage to charge output) andBuck (low voltage to charge the battery), while efficiently managing current in both directions.

2.2. PCB Application In Wireless Power Bank

Wireless Power Bank uses dedicated PCB circuit:

- High frequency resonant circuit:The PCB must be designed to integrate the wireless charging inductor and high frequency processing components, which requires PCB materials with low dielectric loss.

- Heat dissipation:The heat generated from wireless power transmission needs to be tightly controlled by thermal solutions on the PCB.

2.3. PCB For Power Bank With Display Screen

High-end power banks with displays (LED/LCD) require a PCB that not only manages power but also integrates a microcontroller (MCU) to process data and communicate with the display.PCB For Power Bank With DisplayIt is necessary to design separate signal lines to ensure no interference from high power power lines.

3. Special Applications and Durability Requirements

The capacity of Vietnamese PCB manufacturers is also evaluated through their ability to produce circuits for special environments and applications.

3.1. High Temperature Resistant PCB for Outdoor Environment

While power banks are typically used indoors, emergency battery lines or batteries for outdoor devices require PCBs that can withstand high temperatures. High Temperature Resistant PCB for Outdoor Environment High-temperature materials and capacitors and components with wide operating temperature range are required to ensure reliability in harsh climatic conditions.

3.2. PCB Application In Smart Power Bank - MyMy Technology

Smart Power Bank is a big step forward where the PCB integrates Bluetooth/Wi-Fi connectivity for users to monitor battery status via the app. This requires the PCB to handle bothLi-ion/Li-Polymer Battery Control Circuit and wireless communication circuitry, resulting in a complex design and high component density.

3.3. PCB Used in Mobile Rescue Equipment

Portable rescue devices (such as car jump starters) require PCBs that can handle extremely high discharge currents in a short period of time. The PCB needs to have thick copper layers and optimally designed circuits to avoid dangerous voltage drops and overheating.

Conclude

The power bank market is moving towards high-tech integration and absolute safety. To compete, manufacturers need a PCB partner that is capable of mastering the latest technologies. Choosing aPower Bank PCB Manufacturing Company in VietnamReputation and ability to produce complex circuits are decisive factors.

MyMy Technology is one of the leading units, not only specializing in manufacturing high quality PCBs for standard and PCB In Large Capacity Power Bank, but also provides advanced solutions forPCB For Power Bank With Built-in Type-C Port and PCB Application In Wireless Power Bank. By investing in automation technology and adhering to strict quality control standards,Mymy TechnologyEnsure that the factory charging circuits achieve optimal conversion efficiency and the highest safety, helping your power bank products always lead the market.