Prestigious iPhone Charger PCB Circuit Manufacturing Factory in Vietnam

Prestigious iPhone Charger PCB Circuit Manufacturing Factory in Vietnam

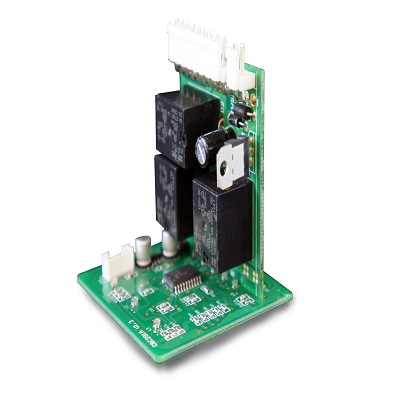

1. PCB circuit

In everyiPhone chargercircuitPCB (Printed Circuit Board)is the most important part – where the entire conversion and stabilization process is controlled. The PCB circuit is responsible for converting alternating current (AC) from the mains into direct current (DC) suitable for charging.pin Li-ionof iPhone.

One standard PCB circuit must ensure 3 factors:

- Stable power source, no fluctuation.

- Smart charging configuration, compatible with each device line.

- Integrated battery protection circuit, avoid overvoltage, overcurrent and overheating.

Thanks to the PCB circuit working correctly, the iPhone canFast charging, stable temperature and long battery life– something that users are always concerned about during long-term use.

2. Standard charging configuration for Li-ion batteries - MyMy Technology

The linespin Li-ion (Lithium-ion) are commonly used in iPhones, iPads, and many mobile devices due to their high energy density, light weight, and fast charging capabilities. However, these batteries are very sensitive to charging temperature and voltage.

Therefore, iPhone charger PCB circuitdesigned withstandard charging configurationcyclicalCC – CV (Constant Current – Constant Voltage):

- CC (Constant Current) Stage:The battery is charged with a steady current until it reaches about 70–80% capacity.

- CV (Constant Voltage) Stage:As the battery nears full, the circuit gradually reduces the current to avoid overloading.

- Smart charging cut-off stage:The battery protection circuit automatically cuts off the current when the battery reaches 100%, ensuring absolute safety.

Common charging configurations:

- 5V–2A: For normal charging.

- 9V–2.2A: For fast charging iPhone 11–15 series.

- 20V–1.5A: For iPad, MacBook mini and universal charger.

Ask for a favor precision voltage-current control circuit, Li-ion batteries are always charged efficiently without being damaged or losing capacity over time.

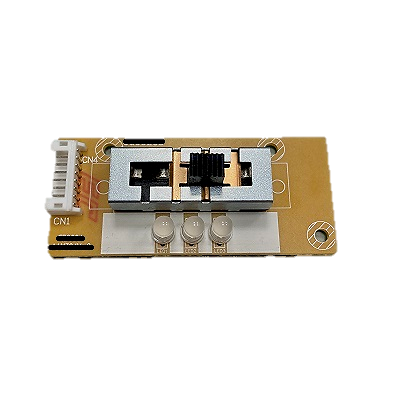

3. Battery protection circuit – a vital element in charging PCB design - MyMy Technology

In the iPhone charger PCB design,Protection Circuit Module (PCM)is an indispensable part. It acts as a “shield” to help the battery avoid dangerous incidents:

- Overcurrent protection:Disconnect power if charging current exceeds allowable threshold.

- Overvoltage protection:Control output voltage not to exceed 4.35V/cell.

- Overheat protection:The heat sensor activates when the battery temperature exceeds 45°C.

- Disconnect the charger when the battery is full:Helps prevent battery swelling or reduced life.

Thanks to this protection circuit, users canCharge your device longer without worrying about battery damage, while ensuring safety in high temperature environments or unstable power sources.

4. Notes when using Li-ion batteries and iPhone chargers - MyMy Technology

Although Li-ion batteries have high durability, for improper use, battery life will be significantly reduced. Here are some important recommendations from theiPhone charger PCB manufacturing factory in Vietnam:

- Do not leave the battery or charger in the car in direct sunlight.

The temperature inside the car can exceed 60°C, causing the battery to blister or burst.

- Avoid charging in environments above 30°C.

High temperature reduces the energy conversion efficiency of the PCB circuit and increases the internal resistance of the battery.

- Do not charge overnight continuously.

Although the protection circuit has a charging cut-off function, maintaining high temperatures for a long time still affects the battery structure.

- It is recommended to maintain battery capacity between 20% and 80%.

This is the safety range that allows Li-ion batteries toMaintains a lifespan of up to 1000–1500 charge cycles.

By following these precautions, users canExtend battery life from 2 to 3 years, significantly reducing the risk of battery failure or reduced charging performance.

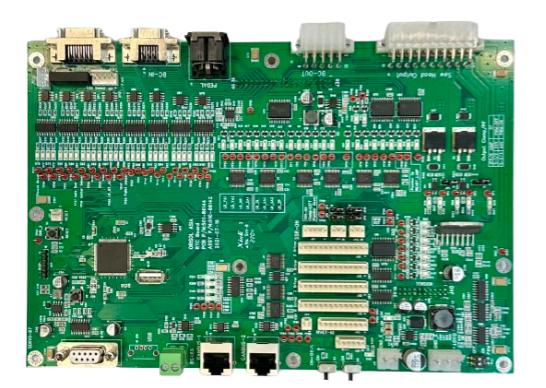

5. iPhone charger PCB manufacturing process in Vietnam - MyMy Technology

ThePCB manufacturing factory in VietnamCurrently applying modern international standard processes:

- Circuit structure design:

Use Altium Designer software to simulate charging configuration and integrate Li-ion battery protection circuit.

- Multilayer PCB printing:

Using high heat resistant FR4 material, copper plating, precise heat pressing.

- Automatic component mounting (SMT – Surface Mount Technology):

Automatic chip mounting machines install ICs, capacitors, inductors, MOSFETs, and thermal sensors.

- Welding and testing:

Reflow soldering – AOI (Automatic Optical Inspection) eliminates microscopic errors.

- Voltage – temperature test:

Each circuit is tested for operation at voltage 5–20V and Simulation temperature 0–40°Cto ensure stable charging current.

Thanks to the closed process, Vietnamese factories canProvide high quality iPhone charger PCB circuit, ensuring stable power supply, compatible with all Apple devices.

Conclude

Choosing a reputable iPhone charger PCB manufacturing factory in Vietnam is the deciding factorCharging performance, battery life and safety in use. A standard charging circuit not only helps Li-ion batteries operate stably but also protects equipment in all temperature conditions.

Special, Do not leave the battery or charger in the car in direct sunlight., and should be charged in a cool environment, below 30°C to maintain long-term performance.

If your business is looking forThe charging circuit supplier integrates battery protection, standard charging configuration and stable current., MyMy Technology is the perfect choice to accompany you in your strategy of developing high-quality electronic products.

Prestigious iPhone Charger PCB Circuit Manufacturing Factory in Vietnam