Prestigious PCB Circuit Board Manufacturing Factory in Vietnam

Prestigious PCB Circuit Board Manufacturing Factory in Vietnam

In the electronics manufacturing industry, PCB (Printed Circuit Board) plays a core role in helping the charger operate stably and safely. In Vietnam, MyMy Technology The factory has mastered the technology of designing and manufacturing iPhone charging circuits, in which the units with specialized research and development (R&D) capabilities stand out, ensuring that each circuit board meets international standards.

How to Determine the Input – Output Requirements of a Charging Circuit

Before designing the charging circuit, the engineer needs to clearly defineInput voltage requirement and output voltage. With an iPhone charger, the input source is usuallyAC 100–240V, and the output isDC 5V – 3A or 9V – 2.2Adepending on the type of fast charger. Determining the correct parameters helps to choose the right components, avoiding overvoltage or overcurrent that can damage the battery and phone circuit.

In addition, the factor/electromagnetic interference (EMI) and energy conversion efficiency should also be carefully considered, especially with high-power fast charging models..

How to Choose the Right Charging IC for Each Battery Type

The charging IC is the “heart” of the PCB circuit. Depending on the iPhone model or battery used, the engineer will choose an IC with the ability to automatically charge current adjustment, overheat protection and protocol compatibility PD (Power Delivery) or QC (Quick Charge).

A good IC helps to control voltage stability, while protecting the device from problems such as short circuit or overcurrent. In mass production, reputable factories in Vietnam often import ICs from Texas Instruments, ensuring global quality.

Current and Voltage Regulator MOSFET Design

MOSFET acts as an “electronic valve”, allowing the regulation of current and voltage during charging. When designing, engineers need to calculate maximum load current, choose the MOSFET type with low conductivity to reduce energy loss.

In modern iPhone chargers, MOSFETs are also used to automatically shut off when detecting high temperatures or abnormal voltages, contributing to increased safety for both the device and the user.

Calculate Resistance In Phone Charging Circuit

Resistance is an important factor that helps stabilize current and protect components. When designing a charging circuit, engineers need to determine the appropriate resistor to limit the charging current and ensure the IC is not overloaded.

Normally, resistors in a circuit are arranged in the feedback circuit and voltage divider, which helps the IC accurately recognize the output voltage level for automatic adjustment.

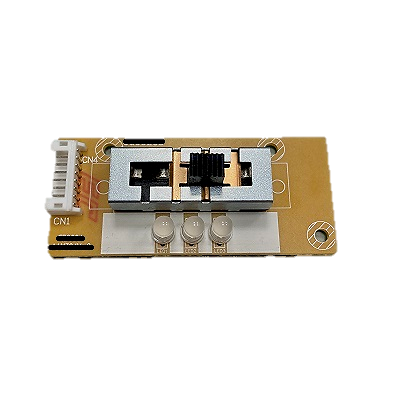

The Role of Protection Diodes in Charging Circuits

Protection diodes prevent reverse current from the battery or device back into the charging circuit, avoiding damage to the IC. In high-quality chargers, the diodeSchottkypopular for its abilityFast switching and low voltage drop, helping to reduce energy loss and increase efficiency.

This is also the reason why PCB factories in Vietnam are currently equipped with reverse current tests before leaving the factory.

Using Capacitors to Filter Noise and Stabilize Power Supply

Capacitors help eliminate unwanted noise and fluctuations in the charging source. Each type of capacitor has its own role:

- Ceramic capacitors: high frequency noise filter.

- Capacitor: stabilize output voltage.

- Tantalum capacitors: Reduces fluctuations during fast charging.

The reasonable combination of capacitors helps the iPhone charger maintain a stable current, avoiding "intermittent charging" or overheating during long-term use.

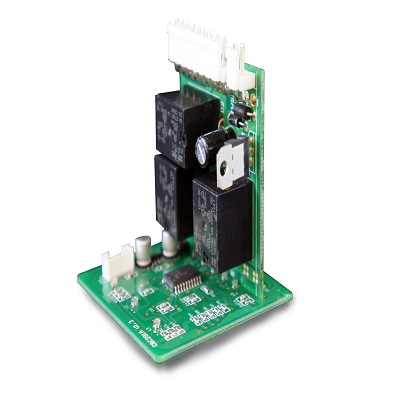

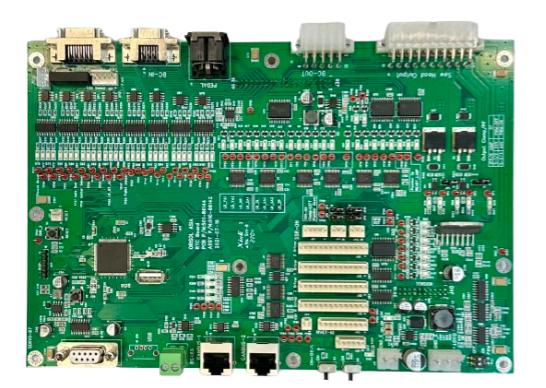

Optimal Component Layout on Printed Circuit Board (PCB)

Once all the components have been identified, the next step is to arrange them on the PCB in the most optimal way. Components/source and control need to be placed close together to reduce signal delay, and filter capacitor and diode should be placed close to the output port to reduce interference.

A neatly and reasonably designed circuit board not only helps save space in the charger but also increases mechanical durability, reducing the risk of damage when dropped or impacted.

PCB Power Trace Design to Reduce Noise

The electrical trace is the deciding factor in the quality of the circuit. Engineers need to ensure that the power and ground lines are separate and have a thickness suitable for the current flowing through them. In addition, the layout ground loop and copper heatsink also contributes to stabilizing the operation of the entire system.

In actual production, reputable factories in Vietnam applyanti-moisture coating and insulating coating technology (coating) to prolong PCB life in harsh environments.

Popular Charging Circuit Drawing and Simulation Software

Currently, iPhone charging circuit design engineers often use specialized software such as:

- Altium Designer– the most professional tool for industrial PCB.

- Proteus– detailed current and component simulation.

- KiCad– open source, easy to use, suitable for standard charging circuits.

Thanks to simulation software applications, factories can test and optimize circuits before mass production, helping to reduce errors and save costs.

Conclude

Job Design and manufacture iPhone charger PCB circuit requires a combination of engineering, technology and practical experience. MyMy Technology Prestigious PCB circuit manufacturer in VietnamToday, not only do we meet international technical standards, but we also proactively improve processes and aim for products.safe - energy saving - environmentally friendly.

Each circuit board created is the crystallization of dozens of testing steps and precise design – the foundation for the most durable and efficient iPhone chargers on the market.

Prestigious PCB Circuit Board Manufacturing Factory in Vietnam