Prestigious Power Bank PCB Circuit Manufacturing Factory in Vietnam

Prestigious Power Bank PCB Circuit Manufacturing Factory in Vietnam

In the context of the power bank market requiring faster charging speed, larger capacity and absolute safety, choosing aPrestigious Power Bank PCB Circuit Manufacturing Factory in VietnamIt is not just about finding a place to manufacture but about finding a partner that provides a complete solution. A reputable factory must be able to support the business from the initial design stage to the after-sales warranty.

Leading PCB factories in Vietnam are building a comprehensive service model, helping electronics brands optimize production processes and minimize business risks.

1. Comprehensive Design and Manufacturing Services

A reputable factory provides a closed process, ensuring quality from drawing to final product.

1.1. Complete PCB Design Service for Businesses - MyMy Technology

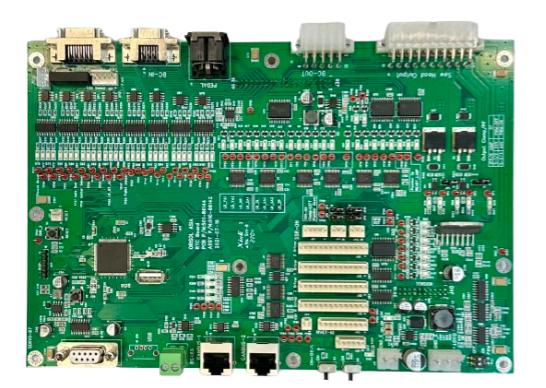

Instead of just taking on processing, top factories provideFull PCB design service for businessesThis service includes:

- Technical requirements analysis:Circuit design based on required charging power, charging standard (USB-PD, QC) and physical size.

- DFM (Design For Manufacturing) Optimization:Ensure circuit designs not only perform well but are also optimized for mass production, minimizing costs and processing times.

- Support sample testing before signing production contract:Provide rapid prototyping services. Customers can test actual performance, heat dissipation and protection features before making mass production decisions, minimizing the risk of design errors.

1.2. Strict Assembly and Quality Control Services - MyMy Technology

The production process of backup charger circuit cannot lack assembly and quality control.

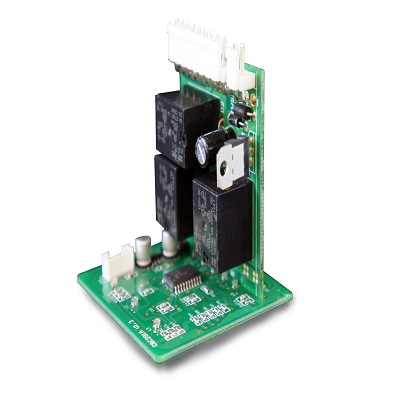

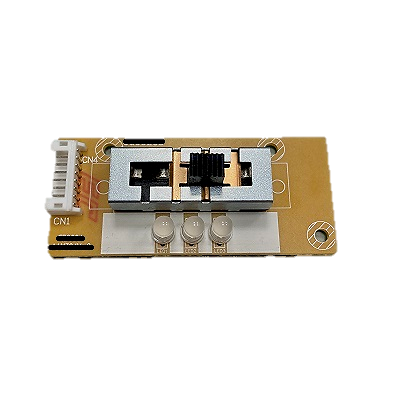

- Electronic component assembly service package on demand (PCBA):The factory provides assembly services for SMT (Surface Mount Technology) and through-hole (THT) components, including component procurement, ensuring clear origin and high quality (such as battery management chips, MOSFETs, capacitors).

- Input-output quality control service (IQC/FQC):Comprehensive quality control process:

- IQC (Input Quality Control):Check the quality of input materials (FR4 base material, components).

- FQC (Final Quality Control):Each finished circuit is electronically tested (E-Test) and functionally tested (Function Test), ensuring the charging circuit operates stably and safely before packaging.

2. Cooperation Policy and Logistics Commitment

The reputation of a factory is demonstrated through the level of commitment and customer support throughout the cooperation process.

2.1. Premium Technical Support and Warranty Policy

The difference between a reputable factory and a regular factory lies in the support service:

- 24/7 technical support from Vietnam factory:Our team of engineers are on hand to resolve any circuit issues that may arise, especially important when customers are in different time zones or need urgent assembly troubleshooting.

- On-site backup charger circuit warranty policy:This is a high-level commitment, demonstrating absolute confidence in product quality. This policy helps businesses minimize costs and warranty time for final products.

2.2. Ensure Progress and Transparent Order Management

Time commitment is a key factor that directly affects the partner's supply chain.

- Commitment to deliver on schedule to partners:The reputable factory uses Lean Manufacturing and automation systems to ensure that Lead Time is maintained as committed.

- How to order and track production progress:Customers are provided with an online or sales representative ordering system, which allows tracking of production progress, from material preparation to final quality control.

3. Pricing Policy and Customer Management - MyMy Technology

A long-term partner needs to have a flexible and transparent financial policy.

3.1. Price List for Manufacturing Backup Charger Circuits in Vietnam

Reputable factories often publishPrice list for manufacturing backup charger circuits in Vietnamdetails, including:

- Cost of base materials (FR4, CEM-3...).

- Technology cost (number of PCB layers, hole size, trace width).

- Cost of component assembly (calculated by number of solder points).

3.2. Flexible Pricing Policy for Loyal Customers

To encourage long-term cooperation, the factory applies:

- Flexible pricing policy for loyal customers:Offer special discounts, volume discounts, or priority production time for repeat orders.

- Cost consulting support:Provide material alternatives or design optimization to achieve customer cost targets while maintaining performance.

Conclude

Cooperating with aPrestigious Power Bank PCB Circuit Manufacturing Factory in Vietnam bring superior competitive advantages in quality, cost and flexibility in the supply chain. A perfect partner must be a place that provides solutions from A to Z, from complete design, component assembly to 24/7 technical support and clear warranty policy.

MyMy Technology is one of the units that meet this high standard.Mymy Technologynot only committedElectronic component assembly service package on demandhigh quality andCommitted to delivering on time, but also set up customer support policies such asSupport sample testing before signing production contract and 24/7 technical support. Select MyMy Technology is the choice of peace of mind about product quality and a sustainable strategic partner, helping your power bank products always lead in performance and safety.

Prestigious Power Bank PCB Circuit Manufacturing Factory in Vietnam