Which Company in Vietnam Produces iPhone Charger PCB Circuit?

Which Company in Vietnam Produces iPhone Charger PCB Circuit?

The demand for high-quality, fast-charging and safe iPhone chargers has fueled the strong growth of the PCB (Printed Circuit Board) manufacturing industry in Vietnam."Which Company in Vietnam Produces iPhone Charger PCB Circuits?"is always asked by businesses looking for a reliable partner. The answer is not only in the name of a company but also in the ability to master new generation PCB technologies, especially in the context of increasing safety and performance requirements.

Reputable manufacturers in Vietnam, such as MyMy Technology, is at the forefront of applying advanced PCB technology trends, turning Vietnam into a center for manufacturing high-quality charging components.

1. New Generation PCB Trends For Fast Charging Batteries

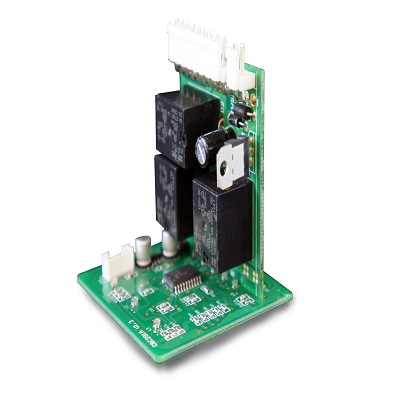

Modern iPhone charger PCBs must integrate many complex technologies to meet fast charging (PD) standards and optimize power.

1.1. Ultra-Thin PCB – Solution for Lightweight Design

To meet the increasingly compact charger design,Ultra Thin PCBare becoming the norm. Ultra-thin circuits require sophisticated manufacturing technology, the ability to drill and plate micro-VIA holes with absolute precision. This is a key trend that helps Vietnamese manufacturers compete in the global supply chain.

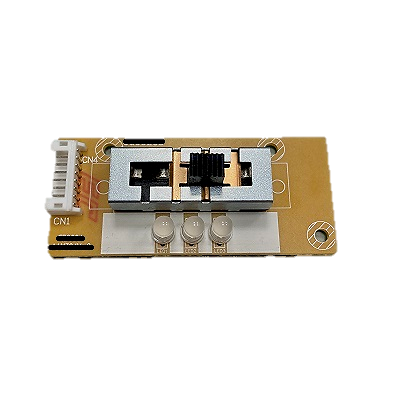

1.2. How Will Integrated Thermal Management Technology Develop?

Thermal management is vital to fast charging.How Will Integrated Thermal Management Technology Develop?The answer lies in the shift from passive to intelligent cooling solutions:

- Integrated temperature sensor:The PCB will integrate the sensor right next to high heat generating components (like GaN chips).

- Dynamic control circuit: The Power Bank of the Future Will Self-Regulate TemperatureBy using smart control chip to reduce charging current when temperature exceeds safe threshold, prolonging battery and component life.

1.3. Solutions to Reduce Energy Loss When Charging - MyMy Technology

Charging efficiency is the ratio of energy going into the device to energy consumed.Solution to Reduce Energy Loss When Charging lies in optimizing the PCB by:

- Low impedance path:Extremely wide and short power supply trace design to minimize 2R resistance and heat loss.

- Using new generation components:Integrate GaN semiconductor components and high quality capacitors to increase conversion efficiency.

2. The Future of Smart Charging and AI Applications

The evolution of PCBs is tied to the integration of artificial intelligence (AI) and automation to enhance safety.

2.1. The Future of Smart Power Banks

The Future of Smart Power Banks is a combination of high quality PCB hardware and AI software:

- Learning Battery Management (Learning BMS):The PCB circuit will collect data on charging habits and battery status to provide an optimal charging schedule, slowing down the battery aging process.

- Self-diagnosis:The PCB is capable of self-testing and reporting errors to the user via the application.

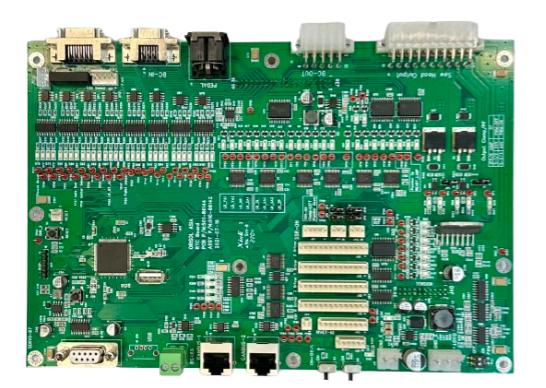

2.2. Automation and AI in Circuit Protection Process

Top PCB factories are moving to the model:

- Automate the Entire Circuit Protection Process:From optical inspection (AOI) to electronic inspection (E-Test) and conformal coating, everything is fully automated, ensuring consistent quality and no human error.

- AI In Overcurrent Control:AI is programmed to analyze current and temperature fluctuations in real time. The system can make faster and more accurate circuit breaker decisions than traditional protection circuits when it detects the risk of overload or short circuit.

3. Green Trends and Sustainable Orientation in Vietnam - MyMy Technology

Vietnam, as a new manufacturing hub, is focusing on sustainability in the production of electronic components.

3.1. Green Trends in PCB Manufacturing

Green Trends in PCB Manufacturing include:

- Environmentally friendly materials:Use halogen-free PCB substrate material to minimize toxic gases during recycling or combustion.

- Waste management:Invest in modern wastewater and chemical treatment systems that meet strict environmental standards.

Compliance with international environmental standards is a mandatory requirement for Vietnamese companies to participate in the supply chain of charger components for major brands such as Apple.

Conclude

To answer the question "Which Company in Vietnam Produces iPhone Charger PCB Circuit?", suppliers need to look for partners that not only have large production capacity but are also technologically pioneering.

MyMy Technology is one of the typical companies in Vietnam oriented towards sustainable and high-tech PCB development. MyMy Technology – Sustainable PCB Technology Orientationnot only expressed through productionUltra Thin PCBfor compact and integrated designThermal Management Technology advanced, but also through investments in automation and environmentally friendly processes.

Which Company in Vietnam Produces iPhone Charger PCB Circuit?