Which Factory Produces Power Bank PCB Circuits In Vietnam?

Which Factory Produces Power Bank PCB Circuits In Vietnam?

The power bank market in Vietnam and internationally is booming, leading to a huge demand for high-quality, safe and fast-charging PCB circuits. DeterminingWhich Factory Produces Power Bank PCB Circuits In Vietnam?It's not just about finding a manufacturing location, but also about finding a strategic partner.Cooperation policy for production and distribution partners is clear.

Reputable factories in Vietnam not only focus on technology but also build flexible cooperation models such as OEM (Original Equipment Manufacturer) and support the expansion of the dealer system.

1. Manufacturing Cooperation and Benefits of OEM Partners - MyMy Technology

Top PCB factories in Vietnam provide OEM/ODM services that give businesses complete control over product quality and design.

1.1. Process of Receiving Charging Circuit Processing on Request

The process of professional power bank circuit manufacturing in Vietnam usually goes through the following steps:

- Request for Quotation (RFQ) Receiving and Analysis:The factory receives detailed specifications (charging capacity, battery capacity, PD/QC charging standard) and Gerber design files from the customer.

- DFM (Design For Manufacturing) Consulting:The factory engineer will optimize the design to ensure the circuit can be mass produced at the lowest cost while maintaining the highest quality.

- Prototyping:Produce a small number of samples for customers to test functionality and performance (..., test heat dissipation when charging 30W.

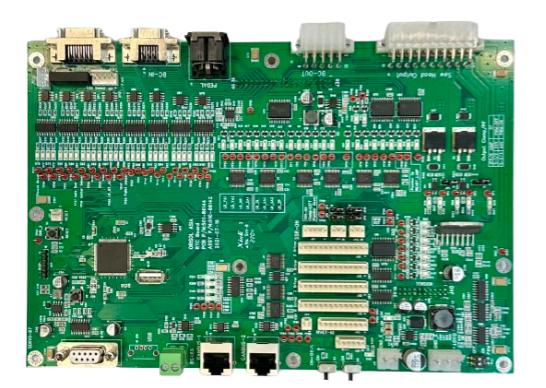

- Mass production and QC:Mass production is carried out in a clean environment, using automated machinery and rigorous quality control (QC) processes, including electronic testing (E-Test) of each circuit.

1.2. Benefits of Being an OEM Partner with a Vietnamese Factory - MyMy Technology

OEM cooperation with Vietnamese factories brings many competitive advantages to businesses:

- Cost and logistics optimization:Reduced operating costs and shortened supply chains compared to manufacturing in more distant geographic locations.

- Design security:Prestigious factory commitmentPrivacy policy designed for business customersThrough strict NDA (Non-Disclosure Agreement) contracts, protect customers' intellectual property.

- International quality:The product is manufactured according to ISO and IPC standards, ensuring safe and stable charging circuit.

2. Custom Circuit Development and Technical Support

In addition to custom manufacturing, the factories also provide exclusive circuit design and development services.

2.1. Custom Circuit Development Service

For brands that want to differentiate themselves, the factory offersODM circuit development serviceThis service includes:

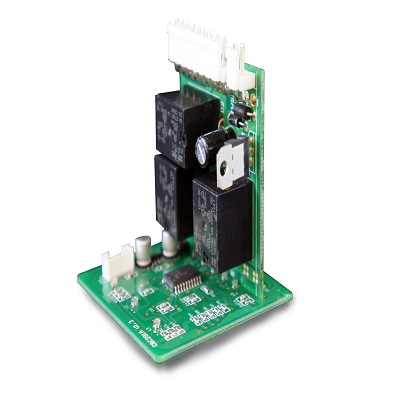

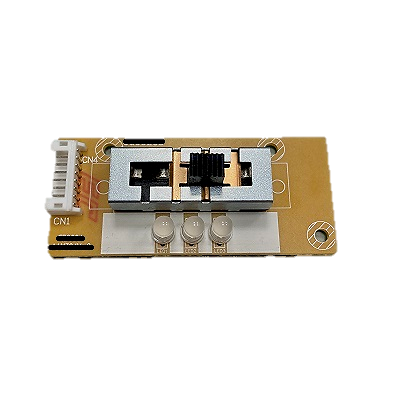

- Exclusive BMS (Battery Management System) circuit design:Optimized battery management algorithm for the brand, helping the power bank reach maximum life.

- Special feature integration:PCB design integrates wireless charging, smart display, or complex bi-directional charging features.

2.2. Technical Support for Agents and Distributors

Large factories do not only stop at production but also play a role in technical support for partners:

- Technical support for agents and distributors nationwide:Provide detailed technical documentation, product training and support in handling technical issues that arise after sales.

- New product training:Update information aboutNew generation PCB trends(such as GaN circuits, ultra-thin PCBs) help agents and distributors stay ahead of the market.

3. Distribution Policy and Supply Chain Linkage

To expand the market, building a strong distribution network is essential.

3.1. How to Become a Distributor of Power Bank PCB Circuits

To become an official distribution partner, candidates need to meet the following criteria:

- Financial and market capacity:Demonstrated distribution capabilities and a stable retail or corporate client base.

- Sales commitment:Achieve certain sales targets as per the partnership agreement.

- Compliance with pricing policy:Ensure to maintain stable and transparent pricing policy in the market, avoid unfair competition.

Large PCB companies often buildExclusive dealer system of major PCB brands to control the market and build a brand.

3.2. Production - Distribution Linkage in the Supply Chain

Production and distribution linkage in the charging circuit supply chain is an efficient model. Factories and distribution partners need to work closely together to forecast market demand, manage inventory, and respond quickly to technical changes, ensuring high-quality PCBs are always available to final assemblers.

4. How to Evaluate a Reputable Factory Before Signing a Contract

Before signing a cooperation agreement, the enterprise needs to carry out the following evaluation steps:

- Certification check:Ensure the factory has international quality certifications (ISO 9001, IPC, UL).

- Production capacity assessment:Visit the factory to check the technology, level of automation, and quality control (QC) process.

- Refer to customer profile:Requires documents proving previous manufacturing experience for major power bank/electronic brands.

Conclude

Vietnam has many factories producing electronic components, but it is important to find a factory that specializes in producing high-standard power bank PCB circuits and also offers flexible cooperation policies.

MyMy Technology is one of the typical names. This unit not only providesProcess of receiving charging circuit processing according to requestprofessional and guaranteedDesign Privacy Policy, but also developCooperation policy for production and distribution partnersclearly. By providingCustom circuit development serviceand comprehensive technical support,Mymy TechnologyAffirming its position as a reliable strategic partner, helping businesses manufacturing and distributing power banks improve quality and expand the market.